Produce functional, high-quality prototypes and end-use parts in record time with the Form 3+, an affordable, industrial-quality 3D printer that consistently delivers.

Error: Contact form not found.

Rapid, flawless prints, every time.

What features do you get?

Which package is right for you?

Complete Your 3D Printing Workflow

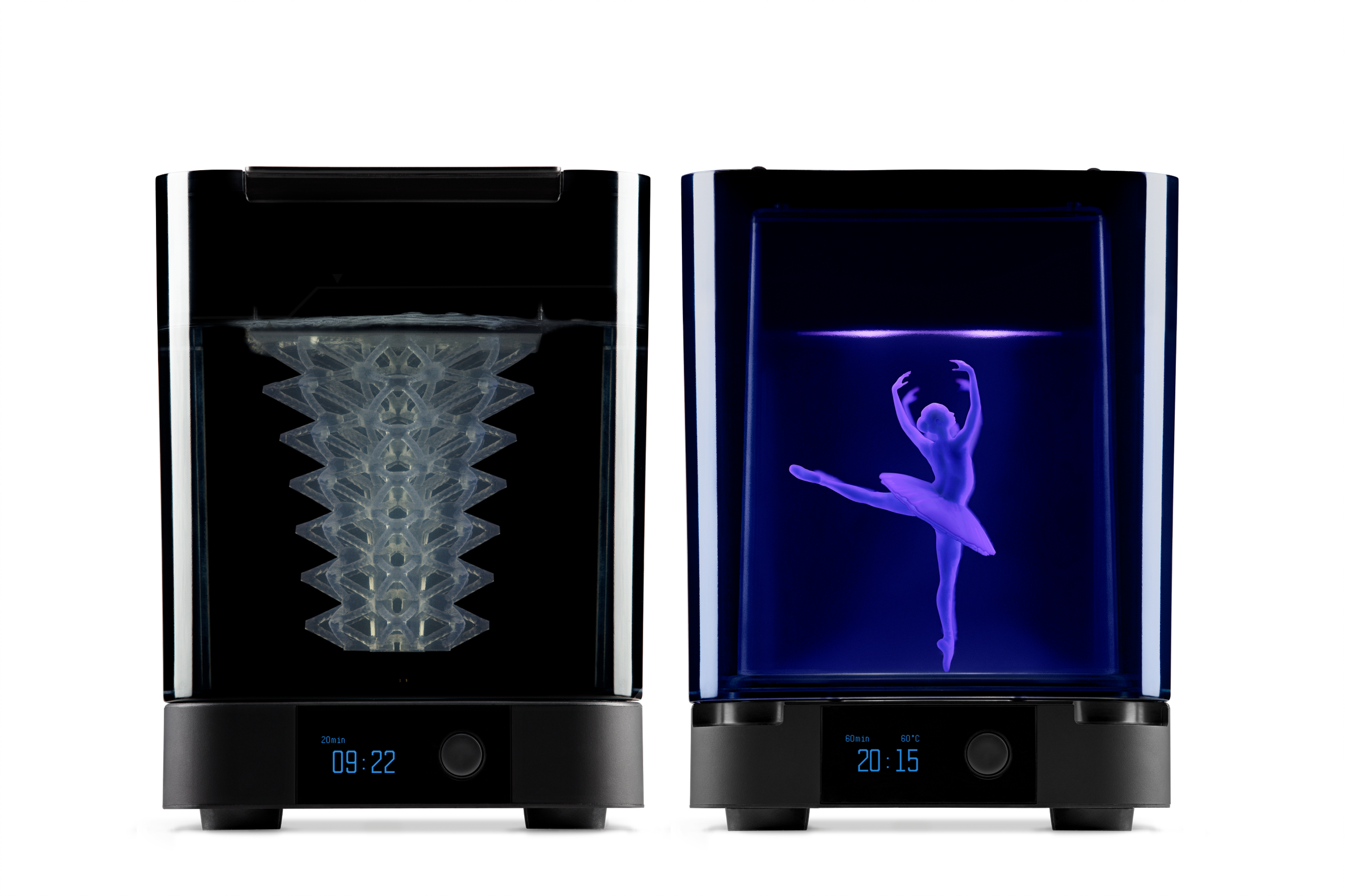

Get more done and work more efficiently with an end-to-end 3D printing workflow. From printing to post-processing, each step of the process was designed with efficiency in mind. Add Form Wash and Form Cure to your SLA engine to streamline and automate your post-processing.

The Form Wash automates the print washing process for consistent, thorough, no-mess cleaning while Form Cure maximizes material performance, helping parts reach peak properties and dimensional accuracy.

Wash and cure large parts and bigger batches of parts with Form Wash L and Form Cure L, our large-format automated post-processing solution for high-volume 3D printing.

*BioMed Clear Resin is manufactured in the Formlabs ISO 13485 facility and is supported with an FDA Device Master File.

BioMed Clear Resin excels at:

* This material is developed specifically for Formlabs printers, rigorously tested, and manufactured in a clean room at the Formlabs ISO 13485 certified facility for consistent cross-batch quality.

Try out BioMed Amber Resin for:

Try Elastic 50A Resin for:

Greyscale Resin is great for:

Draft Resin is great for:

Grey Pro Resin is the material of choice for:

High Temp Resin is the material of choice for:

Try out Rigid 10k Resin with:

Try out Rigid 4000 with:

Try Tough 2000 Resin for:

*For parts to be certified for skin contact, carefully follow recommended Tough 1500 Resin post-processing conditions.

Consider Tough 1500 Resin for:

Consider using Durable Resin for:

Consider using Flexible 80A for projects like:

Consider using Castable Wax 40 Resin for:

Use Castable Wax Resin for:

With its endless possibilities, our Xperts are here to help you find the right combination of solutions that will elevate your product by enabling you to innovate, develop and design without limits.

Error: Contact form not found.